Special machine engineering

Large components milled and turned with maximum precision are vital for flawless functioning of high-tech systems in many areas.

Machine beds serve as base structures for systems that consist of high-precision components.

These components have to be assembled with utmost accuracy relative to one another, and their positions must by no means change during operation. Our machining centers, which are all set up in fully air-conditioned halls and designed for a machining accuracy of 30 µm, can handle components up to 1,950 x 2,950 mm in size and weighing up to 10 t. On our carrousel-type turning lathes, we can machine components with diameters of up to 6,000 mm.

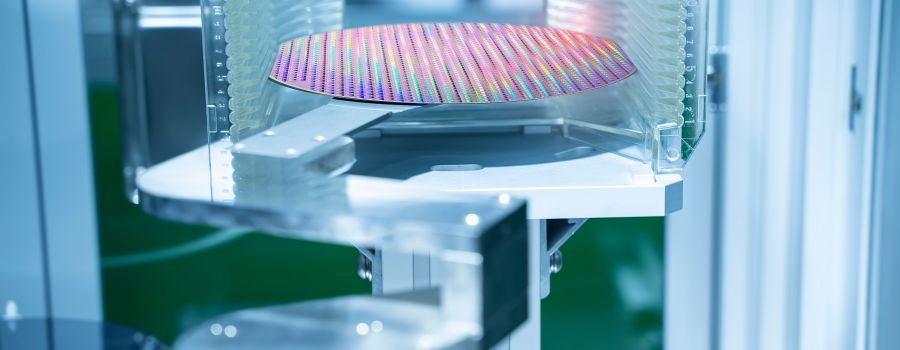

Semi-conductor technology

Components for lithography machines

We supply machine beds to a leading lithography machine producer. These machine beds provide the basis for the high precision needed in wafer production.

Medical technology

Rings for tomography systems

We cast rings with diameters of several meters for computer and magnetic resonance tomography systems. In our machining centers, these rings are manufactured into modules that are ready to install. The outstanding precision of these products guarantees optimal image quality for diagnosis.