New milling center

A new, ultra-high precision milling center is currently being constructed on our premises

The castings and machine components that we produce have to be able to perform reliably under extreme conditions. Therefore, we are committed to meeting the highest quality standards. Customer relations that last for decades prove how dependable we are as a company.

As one of the biggest employers in the region, we have a responsibility to the local community. We are continuously expanding our product portfolio to secure the location for the future and strengthen it for generations to come.

This is one of the reasons why sustainability is of great importance to us. We comply with very high environmental protection standards and work intensively on measures to make our facilities carbon-neutral.

Otto Junker established the company in 1924 in the German town of Lammersdorf, about 20 km from Aachen. During the first decades of its existence, the company, named after its founder, evolved into a medium-sized enterprise focusing on the supply of plants and equipment for the production and processing of metals.

Since the 1950s, the Otto Junker steel foundry has become increasingly specialized in casting and machining components made of high-performance, iron-, nickel- and cobalt-based special alloys and is now a technology leader in the metals industry.

By providing machining services in addition to “just casting”, the foundry has continuously evolved as a supplier of specialist components for demanding uses. Since 2021, it has operated as an independent, wholly-owned subsidiary of OTTO JUNKER GmbH.

This enables both companies to focus on their respective core businesses and customers. Our customers benefit from the intensive exchange of experience between the employees of the various OTTO JUNKER group companies.

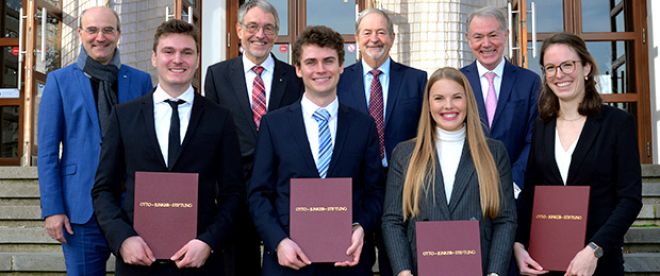

The Foundation awards scholarships to young talent, in particular students at RWTH Aachen University. Several highly qualified graduates and post-graduates from institutes associated with the Aachen university started and are still pursuing their careers at Otto Junker companies.

The photo shows the 2021 scholarship awardees.

A new, ultra-high precision milling center is currently being constructed on our premises

As a carve-out of the special steel foundry, wholly owned by OTTO JUNKER GMBH

at Junker Industrial Equipment s.r.o., in Boskovice, Czech Republic

for the beverage industry

This cooperation still exists today

About 150 employees work at Otto Junker CM GmbH – some of them already in their third generation. The balanced mix of young and seasoned employees ensures that knowledge from decades of experience is transferred from one generation to the next and fresh ideas and innovative techniques are implemented in all areas of our company.

Degree in foundry technology studies from RWTH Aachen University; doctorate from the Faculty of Mining, Metallurgy and Geoscience. With Otto Junker since 2002, initially as Head of the Stainless Steel Foundry and Machining BU; from 2012, COO of Otto Junker GmbH and, since 2021, Managing Director of Otto Junker CM GmbH.

Degree in business management; various controlling positions at a medium-sized business near Aachen. With Otto Junker since 1999, initially in the controlling department until his promotion to Vice Manager Accounting. Since 2021, CFO of Otto Junker CM GmbH.

Many decades of experience and comprehensive know-how combined with the latest scientific findings and technologies guarantee that our castings are always of the highest quality. We are continuously expanding our technology leadership through intensive research and development.

In materials and component development, we work closely with world-leading universities and institutions – and, of course, with our customers – to ensure that we always use the latest equipment and are always at the forefront of alloying expertise.

This includes activities in close cooperation with RWTH Aachen University to advance existing and develop new-generation casting alloys. We also maintain and are continuously expanding technology networks with leading German research institutions.

By continuously optimizing and updating our production facilities with the latest technological features, we ensure that we are always at the cutting edge of technology. This includes enhancing our process reliability and repeatability of production by networking our machinery and systems to an increasing degree within the Internet of Things (IoT) – as well as improving our energy efficiency and making our workplaces safer and our environmental protection even better.